Reliability & ElectroStatic Discharge (ESD) Testing

Reliability Testing

Reliability tests are designed to assess suspected failure modes and problems under carefully controlled and monitored conditions to ensure product quality meets the necessary standard prior to market distribution.�

SETSCO provides a comprehensive range of analytical capabilities to support the needs of the microelectronics industry with techniques to meet the sensitive demands and high-level of precision required for the industry.

Polymer & Organic Material Characterisation

Surface Analysis

Thermal Sh ock

ock

Thermal Shock is a mode of environment testing whereby the objects are exposed to a sudden change in temperature within seconds for a period of times and cycles.

Temperature Humidity

Temperature humidity provides a simulation to the climate condition around the region. High humidity accelerates oxidation and rust in products and increases the conductivity of permeable insulators leading to malfunction in electronic products.

Salt Spray

Our salt spray chamber is designed to test the products ability to saline-induced corrosion. One of industry’s most prominent response to the problem of corrosion caused by salt exposure is plating. Through tests such as salt-spray testing, companies can understand the extent in which their products succumb to corrosion.

Chemical Resistance Test

Chemical resistance test is usually conducted on polymer as polymers are mostly used in casing for products prone to the attack by chemicals. By creating a simulated environment to accelerate the polymer reaction with the various types of chemicals, manufacturers are able to understand and determine the level of resistance to chemical the product is able to withstand.

This is a wet chemistry based test and testing solutions usually include artificial perspiration, sodium carbonate, acetic acid, sucrose, acid and alkaline solutions.

Highly Accelerated Life Test (HALT) / Highly Acclerated Stress Screen (HASS)

HALT and HASS is a test that subjects products to a random six-degree-of-freedom vibration and rapid thermal change rates - in the combined environment necessary to accelerate the failure of the product

ElectroStatic Discharge (ESD) Testing

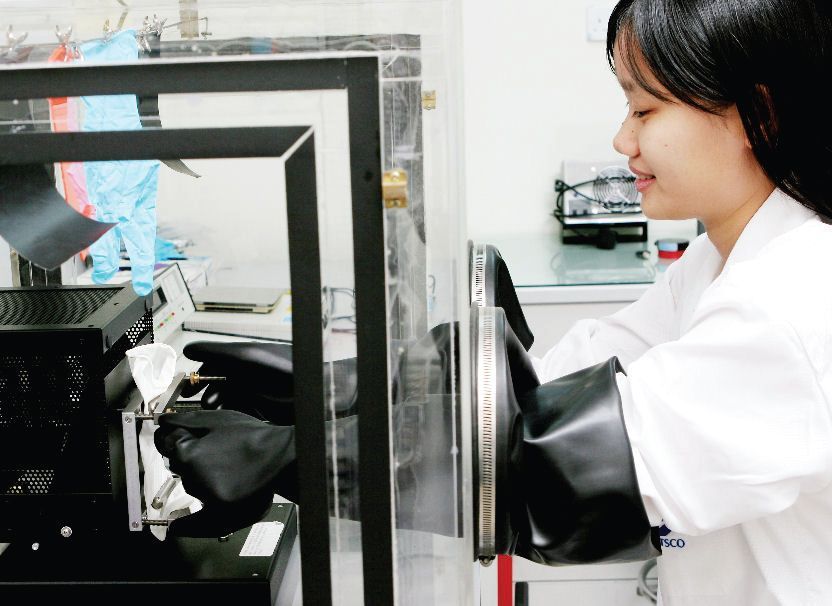

SETSCO’s Electrostatic Discharge (ESD) laboratory is fully in compliance with EOS/ESD standard and specification. Testing are supervised by ESD engineers with iNARTE certification (International Association for Radio Telecommunication and Electromagnetics). Our team of exeperienced and qualified engineers is ableto provide technical consultation, qualifications, survey and audits for the electronics industry.

SETSCO’s Electrostatic Discharge (ESD) laboratory is fully in compliance with EOS/ESD standard and specification. Testing are supervised by ESD engineers with iNARTE certification (International Association for Radio Telecommunication and Electromagnetics). Our team of exeperienced and qualified engineers is ableto provide technical consultation, qualifications, survey and audits for the electronics industry.

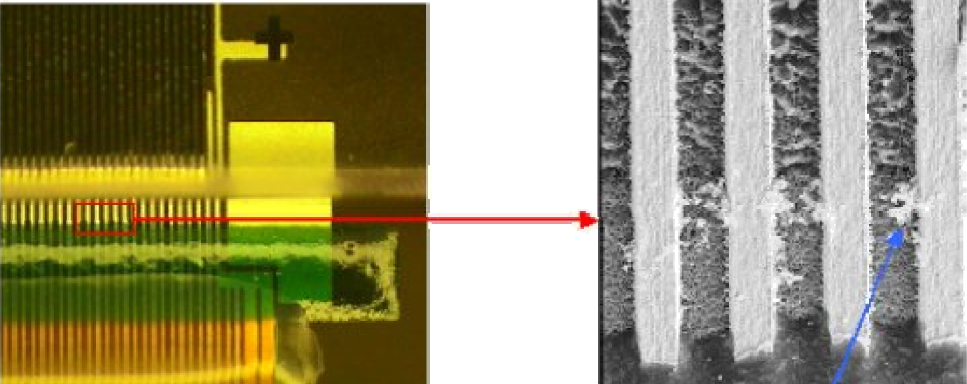

EOS/ESD is more often than not the main cause of semiconductor failure.

SETSCO’s ESD lab is able to help manufacturers reduce loses through ESD testing.

The lab is equipped with various testing equipments to meet the various standards from ESD Association, ESDA standards and others required in the industry.

Types of ESD Testing

•Surface and volume resistance testing and measurement

•Charged plate monitoring

•Static Decay Measurement in humidity chamber

•Footwear - resistive characterization

•Wrist strap system